More about the 8400 Series HMS

8400 Series software capabilities

Sample types

- van der Pauw

- Hall bar 1221 and 1331

Direct measurements

- DC field Hall voltage

- Resistivity

- Ohmic check

- Four-wire resistance

- IV curves

Calculated measurements

- Hall coefficient

- Hall mobility

- Magneto-resistance

- Carrier type

- Carrier density

Field control

- Open-loop DC field control

- Closed-loop DC field control

Temperature control

- Closed-loop

User-defined programs

- Measurement loops for:

- Variable temperature

- Variable gate bias voltage

- Time (repeatability)

- Variable field

- Measurements for:

- DC field Hall voltage

- Resistivity

- Ohmic check

- Four-wire resistance

- IV curves

- Environmental control for:

- Go to temperature

- Go to field

- Go to gate bias voltage

- Wait

Toolbox

- Chart recorder utilities

- DC field voltage vs. time

- Temperature vs. time

- Four-wire resistance vs. time

- DC field calibrations (for open-loop field control)

Reports and exports

- Printing and exporting for Excel®, PDF, and Word®

- Export for QMSA®

Post processing and analysis with QMSA

Lake Shore’s Quantitative Mobility Spectrum Analysis (QMSA) software package represents that most advanced multi-carrier analysis capability available. This exclusive Lake Shore software automatically segregates the mobility spectrum for each carrier species (electrons and holes) that comprise a multilayer or multi-carrier material, including heterostructures, quantum wells, and multiply doped materials. Input for the software analysis includes Hall coefficient, resistivity, and magnetic field. Output parameters include conductivity spectra as a function of mobility, number of carriers (peaks in the mobility graph), density, mobility, and sign of each carrier.

System application software

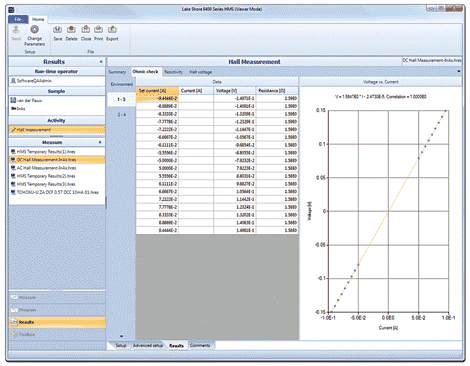

The fully integrated HMS software has a Windows® menu-driven interface for system operation, data acquisition, and analysis.

The menu structure and navigation functions make the platform easy to use. The software controls magnetic field, sample temperature, and sample excitation while delivering a comprehensive collection of measurement capabilities. The sample module ID feature automatically recognizes attached hardware and configures the software accordingly.

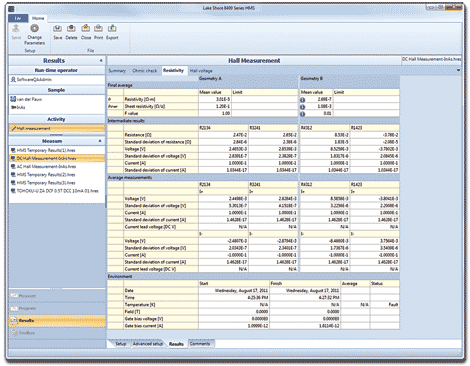

You can define and save specifications and experimental configurations as well as record and display data in laboratory and SI units for further analysis. Real-time feedback of processed data can be displayed in graphical and tabular format. With the software’s SQL reporting capabilities, data and plots can be printed or exported directly to a Microsoft Excel® spreadsheet as well as PDF or Microsoft Word® documents.

To measure sample sheet resistivity, the 8400 Series supports both van der Pauw and Hall bar measurement geometries. The Hall bar method uses one dimensional current flow approximation. You can also measure samples with gated Hall bars to account for gate bias—important for measurement of device-level material. Measure Hall density in a channel as a function of gate voltage and, as you change the gate voltage, create more or fewer carriers. The system’s program mode makes it easy to conduct gated Hall bar measurements. You can, for instance, set up a loop with varying temperatures and gate voltages and easily perform a Hall measurement using the software.

Also, through the software’s toolbox, you have complete control over the measurement parameters and can change them in real time. When combined with environmental settings like temperature, experimental parameters can be quickly determined.

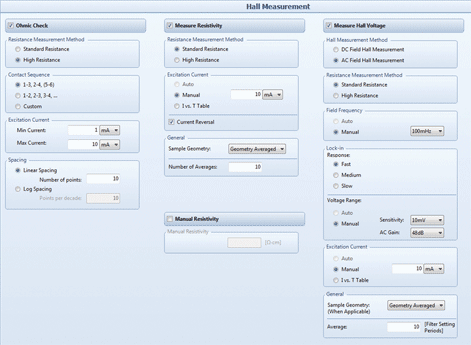

Hall measurement setup

Hall measurement setup is used to define the three basic steps in a Hall measurement. These steps include checking the quality of your sample contacts, measuring the resistivity of your sample and measuring the Hall voltage.

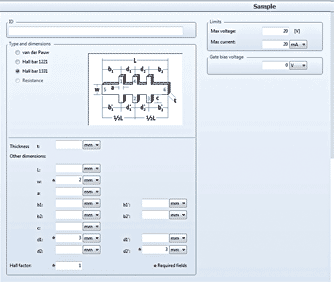

Define a sample

Define your sample geometry and contact arrangement, as well as the maximum voltage and current applied to your sample. Sample definition parameters include thickness and sample dimensions. You can assign sample identifications and add user comments. An ASTM compliance check can also be performed.

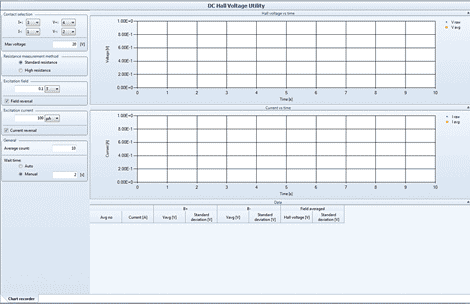

Toolbox

The toolbox includes utilities that allow you to determine measurement parameters, collect and log data, and display the data on screen as a chart recorder. You have complete control over the measurement parameters and can change them in real-time. When combined with environmental settings like temperature, experimental parameters can be quickly determined.

Example of a DC measurement results screen

Example of an ohmic check

Materials

Solar cells Organic electronics | Using the AC measurement option — learn more about it |

Transparent conducting oxides

InSnO (ITO), ZnO, GaZnO, InGaZnO (IGZO)

III-V semiconductors

InP, InSb, InAs, GaN, GaP, GaSb, AlN-based devices, high electron mobility transistors (HEMTs), and heterojunction bipolar transistors

II-VI semiconductors

CdS, CdSe, ZnS, ZnSe, ZnTe, HgCdTe

Elemental semiconductors

Ge, Si on insulator devices (SOI), SiC, doped diamond SiGe based devices: HBTs and FETs

Dilute magnetic semiconductors

GaMnAs, MnZnO

Other conducting materials

Metal oxides

Organic and inorganic conductors

High temperature superconductors

Select system options to fit your applications

A variety of measurement options are available to configure your system for best performance with your samples and their characteristic properties. Parameters to consider when selecting your configuration:1 Mobility range

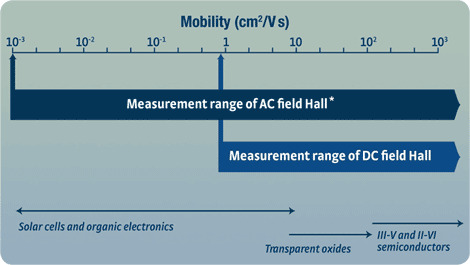

Mobility is one of the most important and commonly derived electronic transport properties measured in an HMS, as it is often directly related to the material performance in an electronic device. The type of magnet field, whether DC or AC, along with the integration of precision electronics and software determines the mobility range you will be able to measure. If you need to analyze materials that fall at the very edge of the mobility range of DC measurements, then consider using the Model 8407. Because it provides higher field strengths, it’s ideal for measuring materials with mobilities from 1 to 106 cm2/V s.

*Available with the 84030 AC option.

The 8400 Series combines the best of both DC and AC field measurement capabilities, which means it has the widest mobility range of any commercially available HMS. The system comes standard equipped with the traditional DC field method, capable of measuring mobilities down to 1 cm2/V s. While the DC field method can measure a wide range of materials, it is not capable of measuring the emerging class of materials characterized by very low mobilities. For these applications, the unique AC field measurement option extends your mobility measurements down to 0.001 cm2/V s.

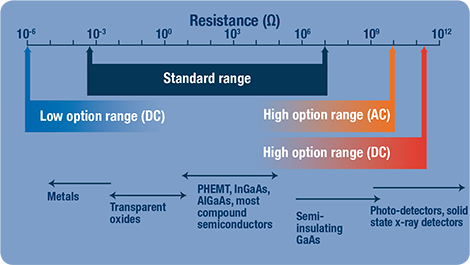

2 Resistance range

Along with Hall mobility and other sample parameters, resistance measurements are one of the fundamental building blocks that define the capabilities and performance specifications of your 8400 Series HMS. In order to enable measurement of the broadest range of materials, it is critical that your system be capable of measuring a very wide range of resistances.

*Available with the 84030 AC option.

Like the mobility range, the 8400 Series offers the widest possible resistance range. The system takes great care in controlling low currents and small voltages present in electron transport systems. While the standard system is capable of measuring resistances from 0.5 mΩ to 10 MΩ, resistance measurement options allow you to measure resistances down to 0.5 µΩ and as high as 200 GΩ when working in DC fields. The high end is limited to 8 GΩ when working in AC field. This wide resistance range ensures you can study the broadest range of materials.

3 Magnet configuration

The magnet is one of the key components of any HMS. It determines, in part, what kind of measurements you can perform. The standard magnet configuration of the 8400 Series is optimized to maximize field strength and ensure uniformity of the field over your sample area. Optional pole cap diameters are available to configure the field and uniformity to your specific requirements. The magnet can also be configured for axial optical access to accommodate lasers and other optical devices.

The magnet is one of the key components of any HMS. It determines, in part, what kind of measurements you can perform. The standard magnet configuration of the 8400 Series is optimized to maximize field strength and ensure uniformity of the field over your sample area. Optional pole cap diameters are available to configure the field and uniformity to your specific requirements. The magnet can also be configured for axial optical access to accommodate lasers and other optical devices.

The unique magnet pole adjustment feature of the 8400 Series takes the guesswork out of setting a consistently repeatable pole gap. It is equipped with spacers that allow you to adjust the gap within a defined set of distances without the use of any measurement tools. You can be confident in your repeatability when changing between pole gaps.

The Model 8404 has a 4 in magnet with a maximum field of 1.67 T, while the Model 8407 has a 7 in magnet with a maximum field of 2.23 T.

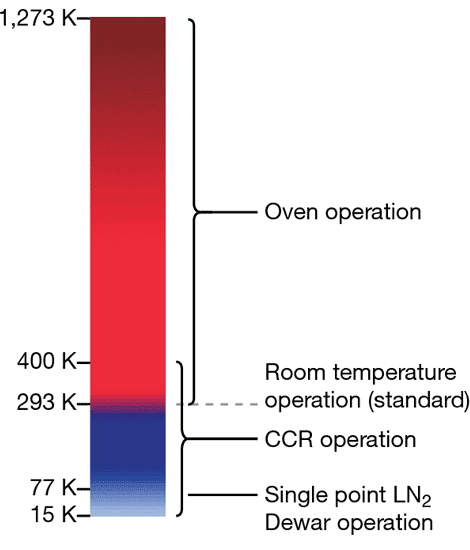

4 Temperature range

While room temperature measurements are sufficient in many cases, transport properties can change significantly as temperature varies. Measuring a sample at variable temperatures allows carriers to be identified by their excitation energies and provides clues to the dominating scattering mechanism. For materials intended for applications requiring variable temperature ranges, testing them at these temperatures can determine their suitability. The 8400 Series is designed to control temperature and magnetic flux to produce accurate, reliable Hall effect and electronic transport measurements.

While room temperature measurements are sufficient in many cases, transport properties can change significantly as temperature varies. Measuring a sample at variable temperatures allows carriers to be identified by their excitation energies and provides clues to the dominating scattering mechanism. For materials intended for applications requiring variable temperature ranges, testing them at these temperatures can determine their suitability. The 8400 Series is designed to control temperature and magnetic flux to produce accurate, reliable Hall effect and electronic transport measurements.

The system is available with a variety of temperature options to further extend its functionality. A single point LN2 body is available if you only need to measure samples at room temperature and at 77 K. A closed cycle refrigerator (CCR) is available for taking measurements from 15 K to 350 K, and an oven extends your temperature measurement capabilities from room temperature to 1,273 K. The 8400 Series is field configurable, so while any of these temperature options can be ordered with a system, they can also be added in the field at any time.

5 Additional measurement options

The 8400 Series options are modular, allowing you to create the exact system you need. Additional measurement options and hardware options can be configured at the time of order, or you can upgrade in the field at any time. This flexibility preserves your investment, allowing you to keep up with the rapidly changing landscape of characterization measurements. Additional future upgrades are also in development.